1 / 3

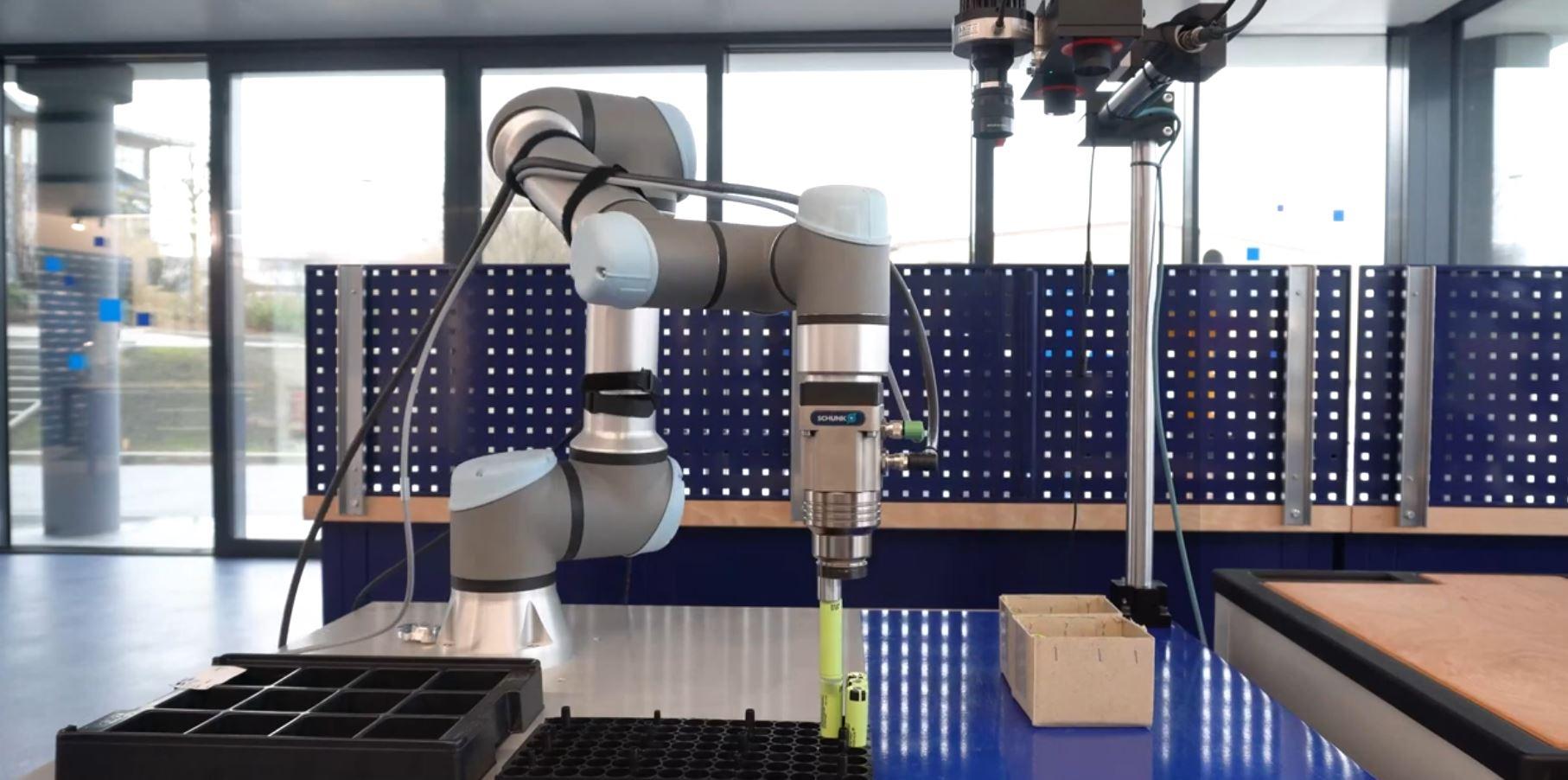

1 / 3Bin picking with a rotary gripper

Test before Invest

Hardware Price:

DOF

3

ROI

3

months

Repeatability

0.5

mm

Efficient Handling of Metal Components with Varioshaker and Robotic Automation

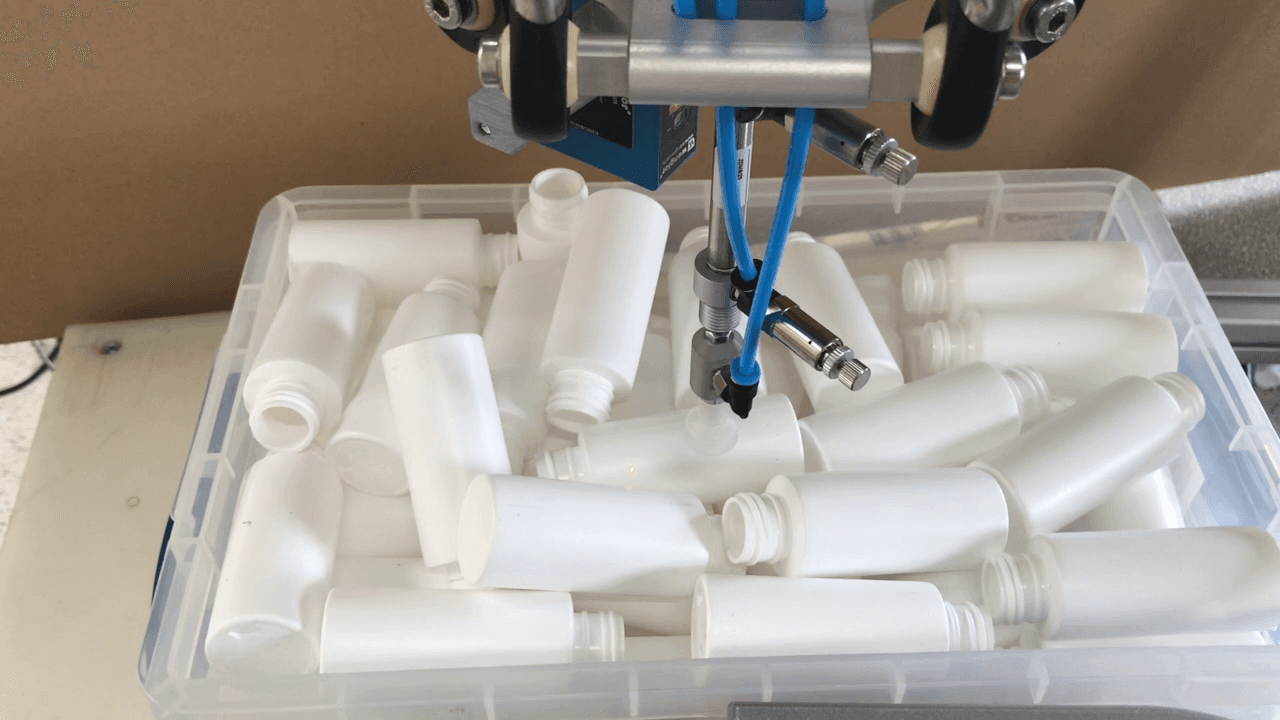

Automating the handling of unsorted metal components revolutionizes productivity in manufacturing. This customer test demonstrates the integration of the Varioshaker device with a robot equipped with advanced gripping technology. The Varioshaker positions unsorted metal components, while a pre-trained camera system captures their exact coordinates and transmits the data to the robot. This ensures precise handling and seamless integration of components into subsequent processes.

What is the Application?

The system automates sorting and handling of metal components, using the Varioshaker to position parts for the camera to identify and the robot to pick and pass on to downstream processes such as assembly or manufacturing.

What are the Advantages of the Solution?

Increased Productivity: Streamlines the transfer of components into manufacturing workflows.

Improved Precision: Advanced image recognition ensures accurate part placement.

Enhanced Quality: Non-damaging handling preserves the integrity of components.

What are the Advantages of the Robot?

The robot, paired with the Varioshaker, offers critical benefits:

High Accuracy: Precise movements informed by real-time camera data.

Versatility: Effectively handles various component shapes and patterns.

Reliability: Continuously operates without human intervention, reducing errors.

Automating Metal Handling for Enhanced Manufacturing Efficiency

By combining the Varioshaker, advanced camera systems, and robotic precision, this solution optimizes the efficient handling of unsorted metal components. With improved accuracy, enhanced product quality, and seamless integration into production lines, it is a valuable automation upgrade for modern manufacturing facilities.

4 Components